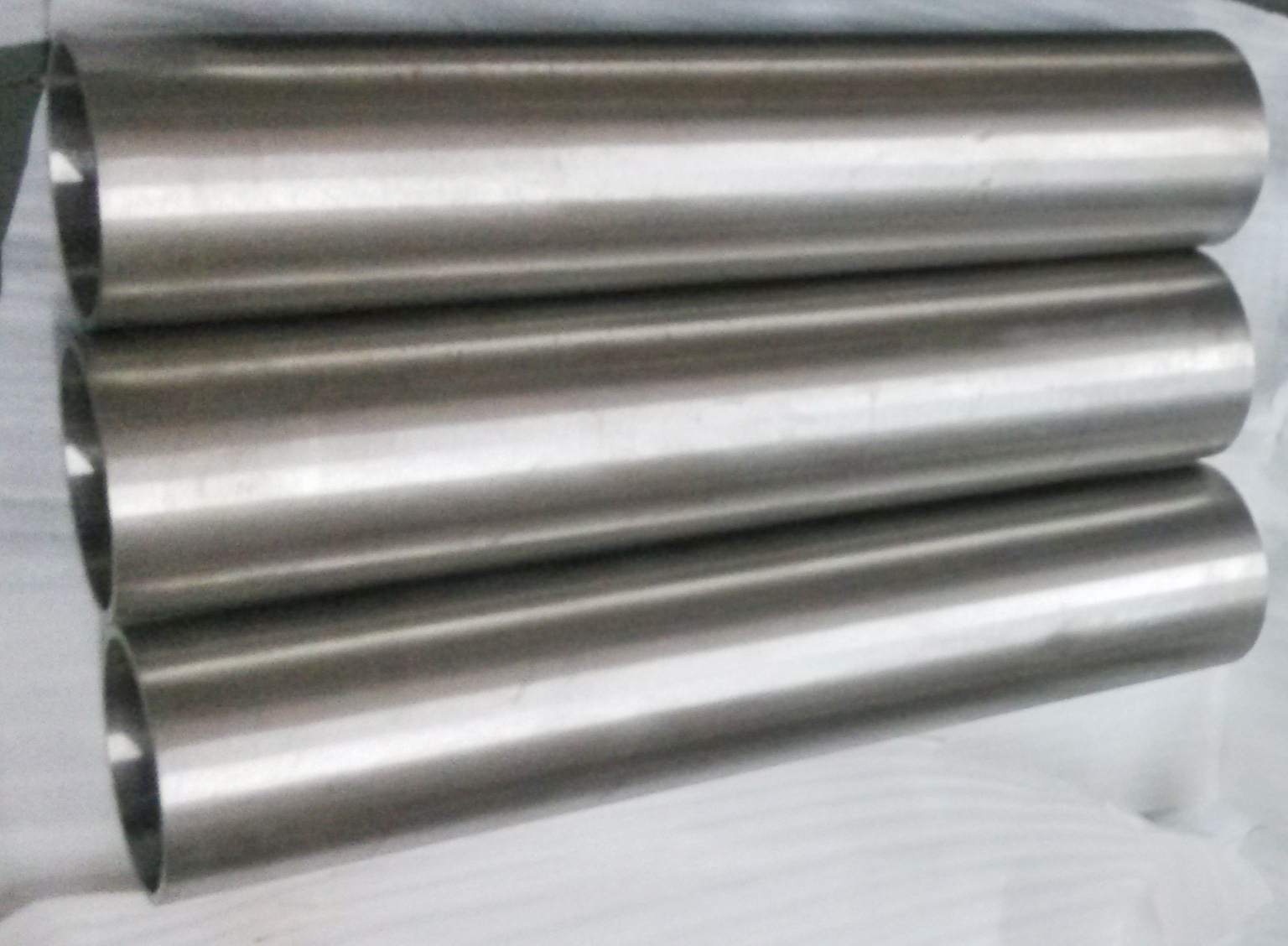

Molybdenum sputtering target

is made of molybdenum by pressing, sintering, machining and flaw detecting.Molybdenum sputtering target applications:

Molybdenum sputtering target can be applied in vacuum coating industry, X ray tube, ion sputtering, flat panel display industry and photovoltaic industry. Molybdenum sputtering target can be used as thin-film solar cell electrode, wiring material and barrier layer material of semiconductor.

High melting point, high electrical conductivity, low specific impedance, good corrosion resistance and excellent environmental protection performance make molybdenum sputtering target form a thin film on various base materials. This kind of sputtering film widely used on electronic components and electronic products, for example, the widely used TFT-LCD (thin film transistor-liquid crystal displays, thin film semi-transistor-liquid crystal display), plasma display screen, thin film solar battery, sensors, semiconductor device and so on.

Characteristics and specifications of molybdenum target:

Molybdenum sputtering target has excellent characteristics of molybdenum, such as high melting point, high electrical conductivity, shiny surface, better corrosion resistance and outstanding environmental protection.

| Purity(%) | Density(g/cm3) | Specifications(mm) |

| ≥99.95 | ≥9.9 |

Round target size: (60-100)dia*(42-55)width Sheet target size: (8-16)thk*(80-200)width*length Tube target size: (70-90.5)outer dia*(7-20)thk*length |