Place of Origin: Henan, China (Mainland)

Brand Name: SANHUI

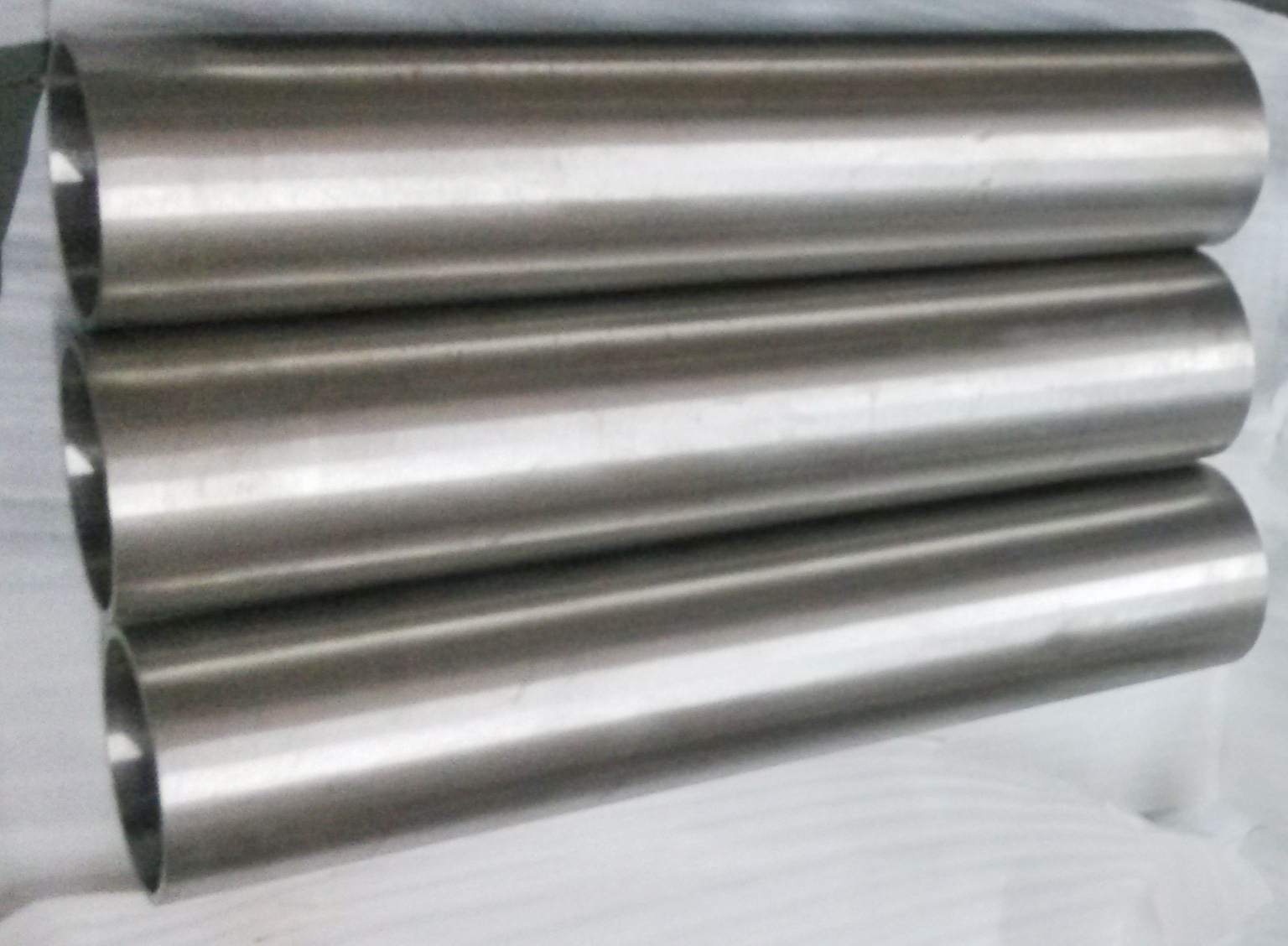

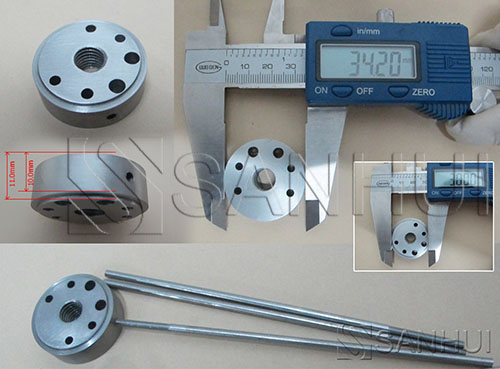

Model Number: Molybdenum machined parts

Application: Vacuum furnace or sapphire crystal growing furnace

Shape: Final machined and bright surface

Material: Pure molybdenum

Dimensions: Customized

Chemical Composition: Mo 99.95%

Standard: ASTM B387

Shape: As per drawing

Application: High-temperature furnace or glass field

Service temperature: Up to 1800 degree

Density: 10.2g/cm3

Certificate: ISO9001:2008

Melting point: 2610C

Dimensions: (0.8-100)*L

Condition: Annealed

Packaging & Delivery

Packaging Details: Plywood case with foam inside

Delivery Detail: 7-20days after order confirmation

Specifications

Moly machined parts

1.High temperature furnace parts

2.1800C temperature

3.As per drawing

4.ASTM B387,ISO

Description:

Standard: ASTM B387

Material: Mo >99.95%

Density: 10.2g/cc

We could offer various molybdenum parts of high temperature furnace as per drawing.

Guaranteed purity:

Working and Machining of Refractory Metals

You can rely on our quality. We produce our molybdenum products ourselves – from the metal oxide right through to the finished product. As our input material, we use only the purest molybdenum oxide. This ensures that you benefit from a very high level of material purity.

Pure molybdenum - or maybe an alloy? It's your choice.

We prepare our molybdenum to perform perfectly in every application. We can determine the following properties through the addition of various alloys:

- Physical properties (e.g. melting point, vapor pressure, density, electrical conductivity, thermal conductivity, thermal expansion, heat capacity)

- Mechanical properties (e.g. strength, fracture behavior, creep resistance, ductility)

- Chemical properties (corrosion resistance, etchability)

- Machinability (e.g. cutting processes, formability, weldability)

- Recrystallization behavior (recrystallization temperature, embrittlement, aging effects)