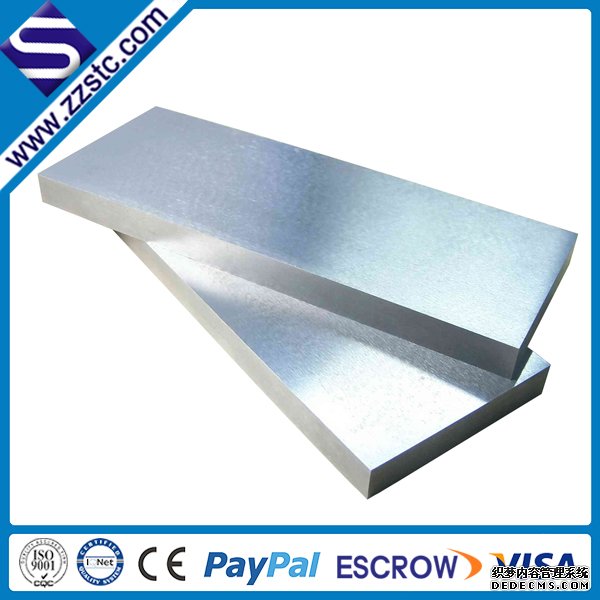

Molybdenum plate can continue to develop in the industry, which is related to its own advantages. The molybdenum plate has good thermal conductivity and electrical conductivity, little reaction thermal, which become an important material for electronic power equipment manufacturing industry. Molybdenum plate can be resistant to high temperature of 28 degrees in vacuum, which is widely used in aerospace, shipbuilding, molybdenum and its alloys can ensure good corrosion resistance, and can reduce the energy consumption.

The application of molybdenum plate is very wide, because it has many characteristics, such as high strength, low coefficient of thermal expansion, excellent thermal conductivity and electric conductivity, higher corrosion resistance to molten glass, molten salt and molten metal, it also can improve the wear resistance of the thin coating. In the following, I will introduce the characteristics of molybdenum plate to you.

1.Good corrosion resistance

The surface of molybdenum plate is easy to produce a dense and strong protective film, which can protect the substrate from corrosion. The casting aluminum alloy with good casting performance can be obtained by the artificial anodic oxidation and coloring, and the deformed aluminum alloy with good plasticity can be obtained.

2.High strength

The strength of molybdenum plate is high. After a certain degree of cold processing, it can strengthen the strength of the matrix, some grades of molybdenum plate can also be processed by heat treatment.

3.Excellent thermal conductivity and electric conductivity

The conductive thermal conductivity of molybdenum plate is only second to that of silver, copper and gold.

4.Small density

The density of the molybdenum plate is about 1/3. of iron or copper.

5.Easy processing