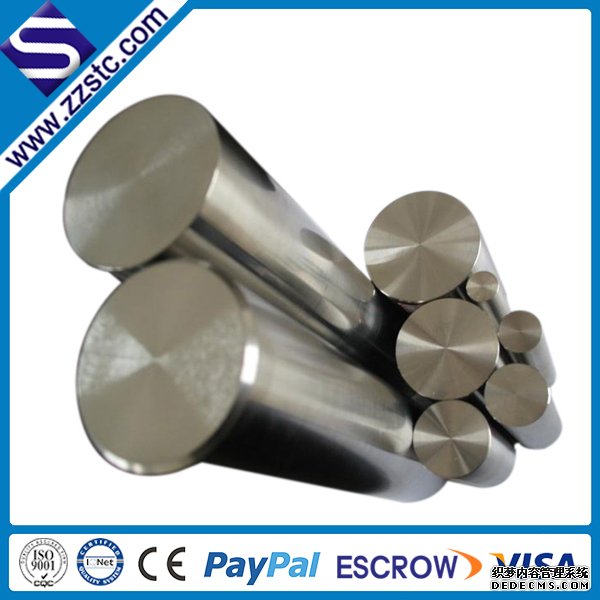

1.The chemical composition of titanium and titanium alloy bars shall be consistent with the requirements, and the allowable deviation of the chemical composition shall be in accordance with the provisions.

2.The diameter or length of thermal processing bar and the deviation should be allowed to meet the provisions.

3.The diameter allowable deviation of cold drawn bar shall comply with the provisions.

4.The roundness of the polishing bar after heat treatment should not be greater than the half of the size tolerance.

5.The length of the rod is 300-6000mm, the length of the annealed bar is 300-2000mm. The allowable deviation of the length of the fixed length is +20mm.

The chemical composition of titanium alloy tube:

GB/T 3620.1—94 the grades and chemical compositions of titanium and titanium alloy.

GB/T 3624—95 the standard of titanium and titanium alloy tube.

GB/T 3625—95 Titanium and titanium alloy tubes for heat exchangers and condenser tubes.

TA1, TA2, TA3 are industrial pure titanium, they have high mechanical properties, good cutting performance and excellent stamping performance, and can be welded, the strength of welding joint can be up to 90% of the strength of the base metal. Titanium tubes have high corrosion resistance to chloride, sulfide and ammonia. The corrosion resistance of titanium in seawater is higher than that of aluminum alloy, stainless steel and nickel base alloy.